Переход ГОСТ 17378-2001 является типом арматуры соединительного характера. Он применяется, чтобы изменить диаметр трубы, при этом трубопровод должен быть расположен исключительно горизонтально. Важно отметить, что соединяются трубы по нижней линии образующего характера.

В основе перехода эксцентрического лежит сталь разных марок. Выбор стали зависит от нескольких параметров переправляемых веществ (например, скорость). Для перехода характерна работа при температуре до 450 градусов и при рабочем давлении не выше 16,0 Мпа.

Таблица 1. Переход ПЭ 159х8,0-108х6,0-20 ГОСТ 17378-2001.

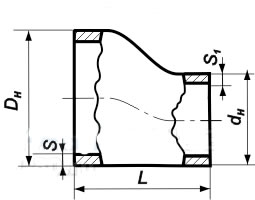

| DN | Dн | S | dн | S1 | L |

|---|---|---|---|---|---|

| 32 | 38 | 4,0 | 25 | 3,0 | 30 |

| 4,0 | 32 | 4,0 | 30 | ||

| 40 | 45 | 4,0 | 25 | 3,0 | 30 |

| 4,0 | 32 | 4,0 | 30 | ||

| 4,0 | 38 | 4,0 | 30 | ||

| 50 | 57 | 5,0 | 25 | 1,6 | 45 |

| 5,0 | 32 | 3,0 | 45 | ||

| 4,0 | 38 | 2,0 | 45 | ||

| 4,0 | 45 | 4,0 | 60 | ||

| 65 | 76 | 7,0 | 38 | 4,0 | 55 |

| 6,0 | 57 | 5,0 | 70 | ||

| 80 | 89 | 6,0 | 45 | 4,0 | 75 |

| 6,0 | 57 | 4,0 | 75 | ||

| 6,0 | 5,0 | 75 | |||

| 3,5 | 76 | 3,5 | 75 | ||

| 6,0 | 5,0 | 75 | |||

| 8,0 | 6,0 | 75 | |||

| 100 | 108 | 4,0 | 57 | 3,0 | 80 |

| 6,0 | 4,0 | 80 | |||

| 4,0 | 76 | 3,5 | 80 | ||

| 6,0 | 5,0 | 80 | |||

| 9,0 | 7,0 | 80 | |||

| 4,0 | 89 | 3,5 | 80 | ||

| 6,0 | 6,0 | 80 | |||

| 9,0 | 8,0 | 80 | |||

| 114 | 9,0 | 57 | 6,0 | 80 | |

| 9,0 | 76 | 7,0 | 80 | ||

| 9,0 | 89 | 8,0 | 80 | ||

| 125 | 133 | 10,0 | 57 | 5,0 | 100 |

| 10,0 | 76 | 6,0 | 100 | ||

| 8,0 | 89 | 6,0 | 100 | ||

| 6,0 | 108 | 6,0 | 100 | ||

| 10,0 | 9,0 | 100 | |||

| 10,0 | 114 | 9,0 | 100 | ||

| 150 | 159 | 12,0 | 57 | 6,0 | 130* |

| 12,0 | 76 | 7,0 | 130* | ||

| 4,5 | 89 | 3,5 | 130 | ||

| 8,0 | 6,0 | 130 | |||

| 6,0 | 108 | 5,0 | 130 | ||

| 8,0 | 6,0 | 130 | |||

| 12,0 | 114 | 9,0 | 130 | ||

| 6,0 | 133 | 6,0 | 130 | ||

| 168 | 12,0 | 57 | 6,0 | 130* | |

| 12,0 | 76 | 7,0 | 130* | ||

| 12,0 | 89 | 8,0 | 130 | ||

| 12,0 | 108 | 9,0 | 130 | ||

| 12,0 | 114 | 9,0 | 130 | ||

| 12,0 | 133 | 10,0 | 130 | ||

| 200 | 219 | 16,0 | 89 | 8,0 | 140* |

| 16,0 | 114 | 9,0 | 140* | ||

| 16,0 | 108 | 9,0 | 140* | ||

| 16,0 | 133 | 10,0 | 140 | ||

| 8,0 | 159 | 6,0 | 140 | ||

| 10,0 | 8,0 | 140 | |||

| 16,0 | 168 | 12,0 | 140 | ||

| 250 | 273 | 18,0 | 108 | 9,0 | 180* |

| 18,0 | 114 | 9,0 | 180* | ||

| 18,0 | 133 | 10,0 | 180* | ||

| 18,0 | 159 | 12,0 | 180 | ||

| 18,0 | 168 | 12,0 | 180 | ||

| 10,0 | 219 | 8,0 | 180 | ||

| 300 | 325 | 22,0 | 108 | 9,0 | 300* |

| 22,0 | 114 | 9,0 | 300* | ||

| 22,0 | 133 | 10,0 | 220* | ||

| 22,0 | 159 | 12,0 | 220* | ||

| 22,0 | 168 | 12,0 | 220* | ||

| 22,0 | 219 | 16,0 | 180 | ||

| 10,0 | 273 | 8,0 | 180 | ||

| 12,0 | 10,0 | 180 | |||

| 350 | 377 | 26,0 | 159 | 12,0 | 300* |

| 26,0 | 168 | 12,0 | 300* | ||

| 26,0 | 219 | 16,0 | 220 | ||

| 26,0 | 273 | 18,0 | 220 | ||

| 12,0 | 325 | 12,0 | 220 | ||

| 400 | 426 | 28,0 | 159 | 12,0 | 300* |

| 28,0 | 168 | 12,0 | 300* | ||

| 28,0 | 219 | 16,0 | 300* | ||

| 28,0 | 273 | 18,0 | 220 | ||

| 28,0 | 325 | 22,0 | 220 | ||

| 10,0 | 377 | 10,0 | 220 | ||

| 14,0 | 14,0 | 220 | |||

| 500 | 530 | 26,0 | 377 | 22,0 | 300 |

| 26,0 | 426 | 22,0 | 300 |

* Указанные размеры отличаются от размеров по ГОСТ 17378-01